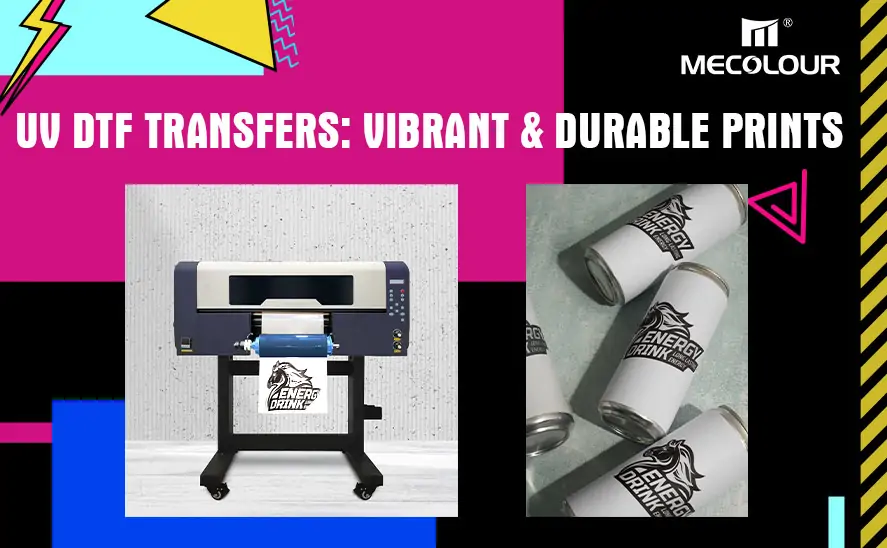

UV DTF Transfers: Vibrant & Durable Prints

In the dynamic world of digital printing, UV DTF transfers stand out as a game-changer. Offering unparalleled versatility and quality, UV DTF transfers have revolutionized the way designs are applied to various surfaces.

What is a UV DTF Transfer?

UV DTF, or Ultra-Violet Direct to Film, transfers involve a cutting-edge printing technique where designs are printed onto a specialized film. This film is then directly applied to different surfaces, resulting in vibrant, durable prints. The UV curing process ensures a strong bond between the ink and the substrate, creating stunning visuals with exceptional longevity.

Benefits of UV DTF Transfer

Unparalleled Print Quality

One of the standout features of UV DTF transfers is the exceptional print quality they deliver. The specialized PVC film and UV-curable inks used in this process ensure that every design is reproduced with stunning vibrancy, sharpness, and detail.

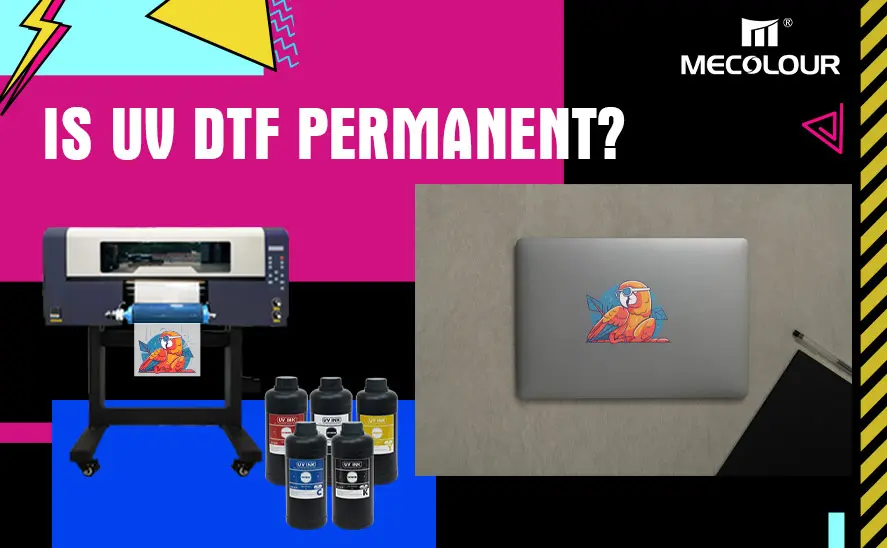

Durability that Defies the Elements

Durability is a hallmark of UV DTF transfers, making them an ideal choice for applications that demand longevity. The UV-cured inks used in this process are highly resistant to fading, cracking, and peeling, ensuring that your prints maintain their vibrant appearance even after repeated washing or exposure to harsh conditions.

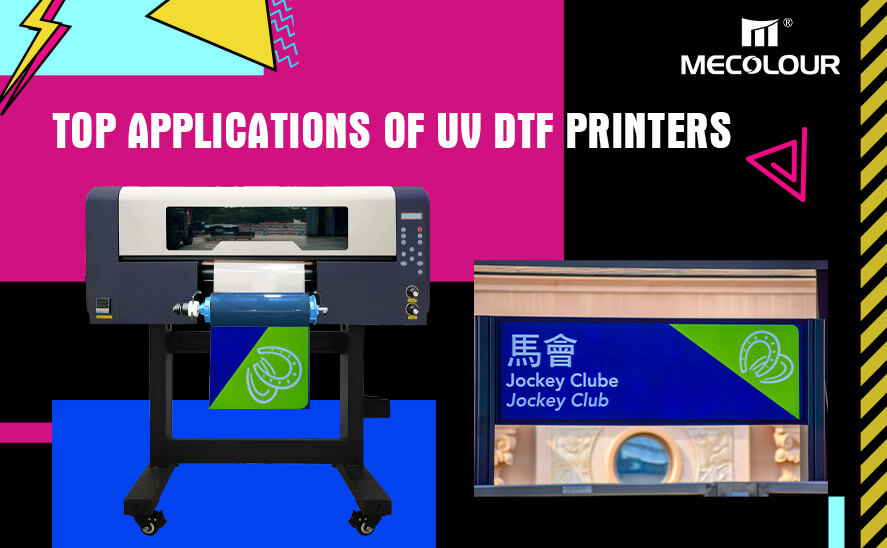

Versatility Across a Wide Range of Substrates

One of the most significant advantages of UV DTF transfers is their versatility. This technology can be applied to a wide range of materials, including ceramics, wood, metal, glass, plastics, and leather, but not textiles.

Cost-Effective and Efficient

Compared to traditional printing methods, UV DTF transfers offer a cost-effective solution, especially for small to medium-sized print runs. The automated process ensures quick turnaround times, eliminating the need for lengthy drying periods. Additionally, UV DTF transfer eliminate the need for expensive screens, plates, or dies, further reducing production costs.

Environmentally Conscious

In today’s eco-conscious world, sustainability is a crucial consideration. UV DTF transfers utilize eco-friendly inks with low levels of volatile organic compounds (VOCs), making them a safer and more environmentally responsible choice. Furthermore, the high quality of UV DTF prints reduces the likelihood of them ending up as waste, contributing to a more sustainable printing industry.

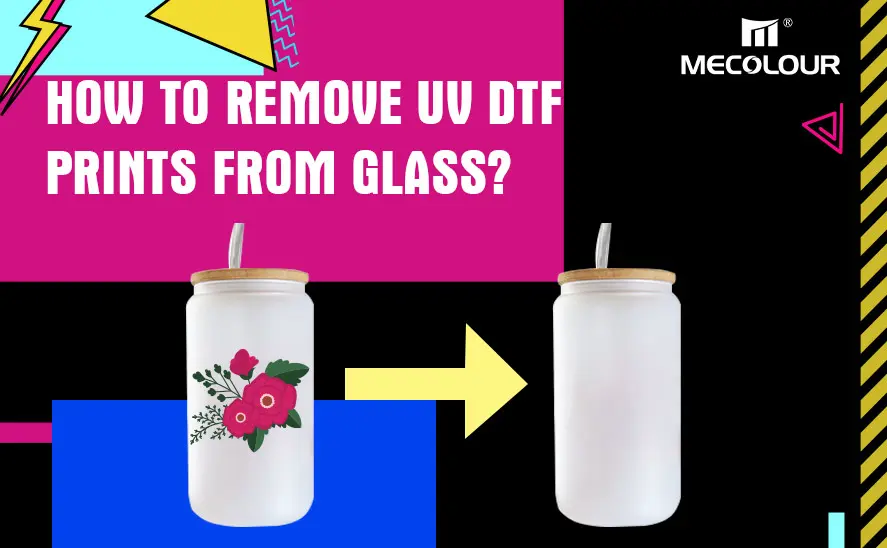

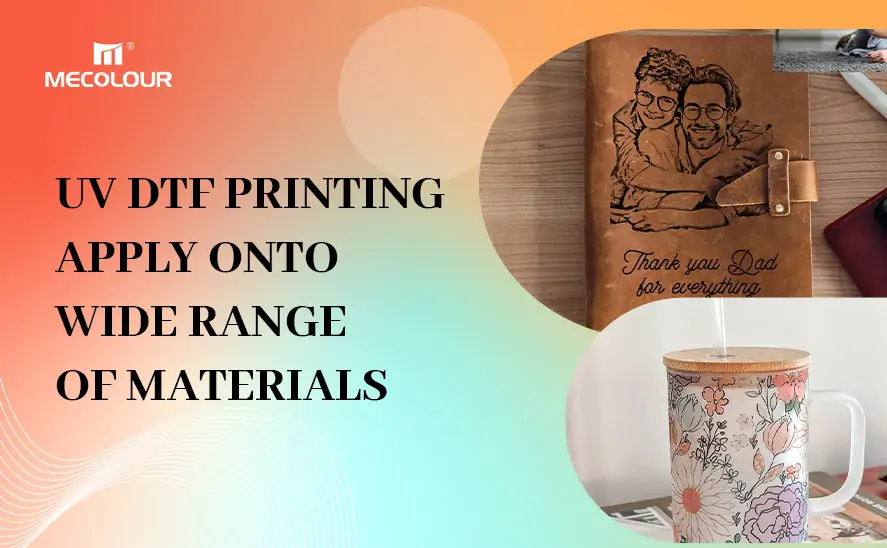

What Materials Can UV DTF Be Applied to?

UV DTF printing offers a versatile solution for applying vibrant, full-color designs onto a wide range of materials, including wood, plastics, ceramics, leather, paper, glass, aluminum, stainless steel, and brass. This versatility stems from the printing process, which involves applying the design onto a film and then transferring it onto the desired surface.

The ability to print on curved and uneven surfaces makes UV DTF suitable for decorating items such as cups, mugs, glasses, and plates.

UV DTF printing apply onto wide range of materials

How Long Does It Take for UV DTF to Cure?

The curing time for UV DTF transfer is remarkably short, thanks to the efficiency of the UV curing process:

Immediate Curing

Upon exposure to UV light, the inks in UV DTF transfer cure instantly. This eliminates the need for extended drying times, allowing for rapid production and turnaround.

Efficiency in Production

The quick curing time enhances overall production efficiency, enabling businesses to meet tight deadlines and deliver high-quality prints without delay.

Consistency and Quality

The instant curing process ensures consistent, high-quality results with every print. From small-scale projects to large-volume orders, UV DTF transfers maintain their vibrancy and durability, meeting the highest standards of excellence.

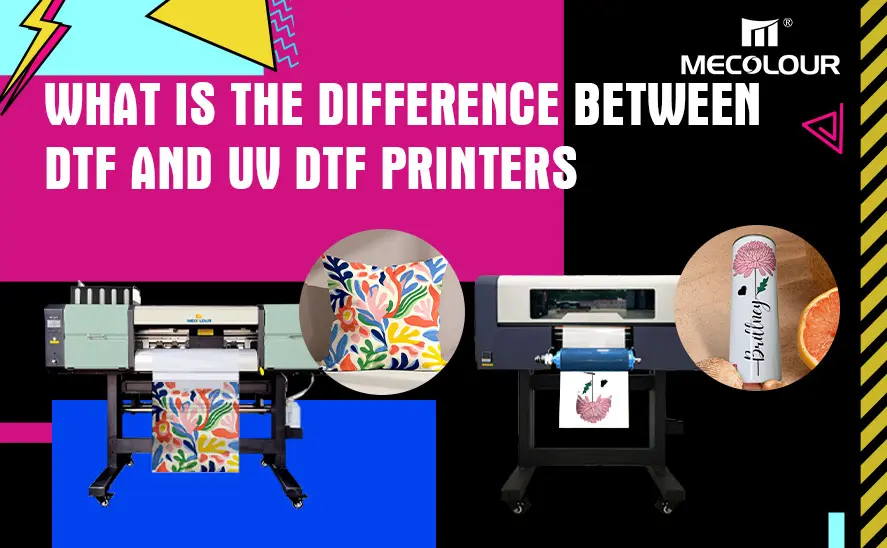

Can I use UV DTF on shirts?

UV DTF (Direct to Film) printing is not the ideal choice for printing directly onto shirts or other textile garments. The UV-curable inks used in this process do not adhere well to fabric fibers, leading to potential issues such as peeling or cracking over time. Additionally, the flexible nature of fabrics and their tendency to stretch can cause the printed design to crack or the transfers to detach.

However, there is a solution for those seeking to apply vibrant, full-color designs onto shirts and other apparel items. The DTF (Direct to Film/Garment) printing method is specifically designed for textile applications. This process involves printing the design onto a specialized film and then transferring it onto the fabric using a heat press.

Moreover, DTF printing is not limited to just shirts; it can be used to decorate a wide range of textile products, including hats, bags, shoes, and more. This versatility, combined with the ability to reproduce intricate designs and vibrant colors. It makes DTF printing an excellent choice for creating custom apparel, promotional products, and personalized fashion items.

Is UV DTF Waterproof?

Yes, UV DTF transfers are waterproof, making them suitable for a wide range of applications:

Water-Resistant Inks

The inks used in UV DTF transfers are specifically formulated to resist water, ensuring that the prints remain intact and vibrant even when exposed to moisture.

Outdoor Use

Due to their waterproof properties, UV DTF transfers are ideal for outdoor applications such as signage, banners, and promotional materials. They withstand the elements with ease, maintaining their visual appeal in any environment.

Durability in Harsh Conditions

UV DTF prints are not only waterproof but also resistant to UV rays and abrasion, ensuring longevity even in challenging conditions. This durability makes them a reliable choice for various outdoor and high-traffic settings.

Applications on Various Products

From water bottles to outdoor equipment, UV DTF transfers offer waterproof customization options for a wide range of products, enhancing their visual appeal and durability.

uv dtf prints

In conclusion, UV DTF transfers represent a cutting-edge solution for businesses and individuals seeking high-quality, customizable prints. With their vibrant colors, durability, versatility, and waterproof properties, UV DTF transfers open up a world of possibilities for creative expression and brand enhancement.