In the world of custom printing, choosing the right technology can be daunting. With various options available, it’s crucial to understand the differences and benefits of each. Today, we’ll dive into a detailed comparison of UV DTF printers and DTG technology to help you make an informed decision.

Overview of Printing Technologies

Printing technology has evolved significantly over the years. From screen printing to modern digital methods, each technology offers unique advantages. Understanding these technologies is key to selecting the best one for your needs.

Importance of Choosing the Right Printer

The right printer can make a huge difference in terms of print quality, cost efficiency, and suitability for various applications. Whether you’re a business owner or a hobbyist, making an informed choice is essential.

Understanding UV DTF Printers

What is UV DTF Printing?

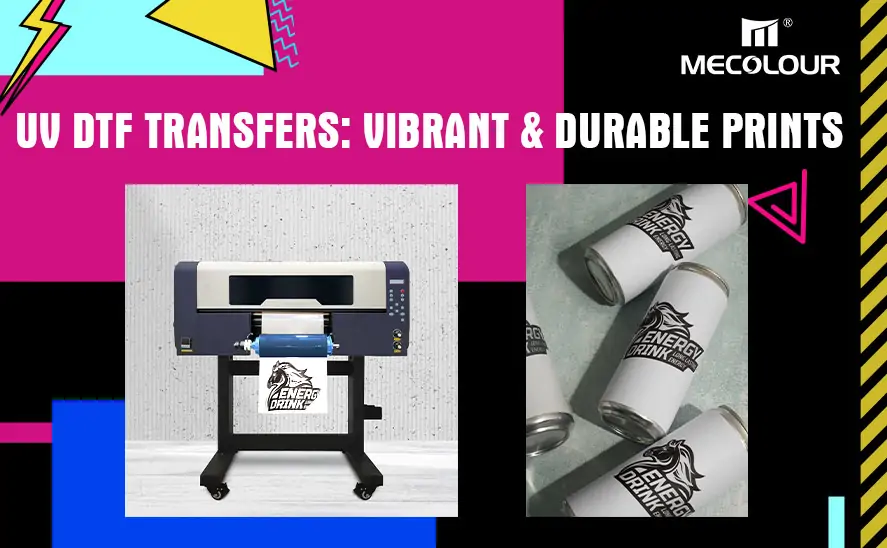

UV DTF (Direct to Film) printing is a relatively new method that combines UV printing technology with film transfer techniques. This process allows for high-quality prints on a variety of substrates.

How UV DTF Printers Work

UV DTF printers use UV light to cure inks directly onto a film, which is then transferred to the desired surface. This method ensures vibrant colors and sharp details.

Pros of UV DTF Printing

– Versatility: Can print on a wide range of materials, including plastics, glass, and metal.

– Durability: UV-cured inks are resistant to fading and wear.

– High Resolution: Produces detailed and vibrant prints.

Cons of UV DTF Printing

– Initial Cost: Higher upfront investment compared to some other printing technologies.

– Complex Process: Requires precise handling and setup.

Understanding DTG Printers

What is DTG Printing?

DTG (Direct to Garment) printing is a popular method for printing directly onto textiles, particularly apparel. This technology is known for its ability to produce high-quality prints on cotton and cotton-blend fabrics.

How DTG Printers Work

DTG printers operate much like traditional inkjet printers, but they use specialized textile inks. The fabric is pre-treated, printed on, and then heat-set to ensure durability.

Pros of DTG Printing

– Detail and Color Accuracy: Excellent for detailed designs and vibrant colors.

– Ease of Use: User-friendly setup and operation.

– Flexibility: Ideal for small batches and custom orders.

Cons of DTG Printing

– Material Limitation: Best suited for cotton-based fabrics.

– Ink Cost: Specialized inks can be expensive.

UV DTF vs. DTG: Head-to-Head Comparison

Print Quality

UV DTF printers excel in producing sharp, detailed images with vibrant colors on various materials. DTG printers are also known for high-quality prints but are generally limited to textiles.

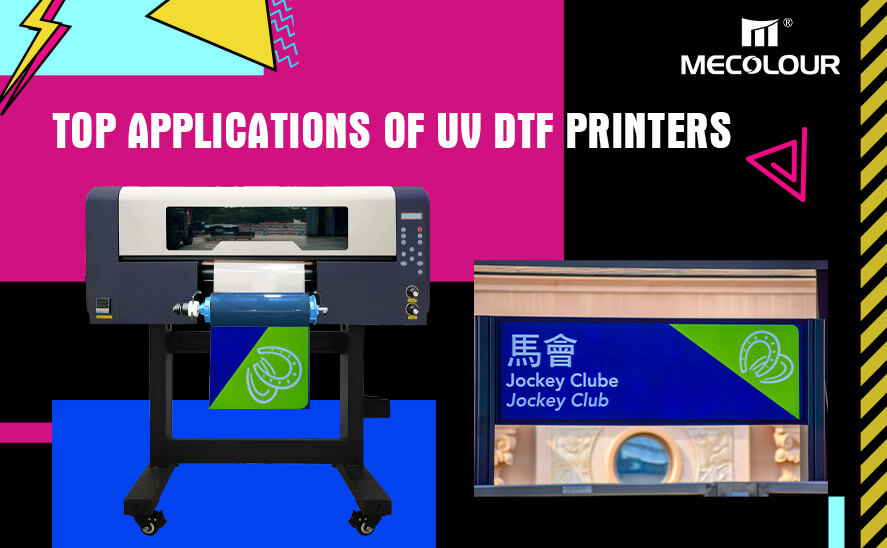

Material Compatibility

UV DTF printing is highly versatile, compatible with numerous substrates like plastic, glass, and metal. In contrast, DTG printing is primarily used for cotton and cotton-blend fabrics.

Cost Efficiency

While UV DTF printers may require a higher initial investment, they offer long-term savings through durable prints and versatile material use. DTG printers are cost-effective for textile printing but can become expensive due to the cost of specialized inks.

Speed and Efficiency

UV DTF printing can be more complex and time-consuming due to the multi-step process. DTG printing, on the other hand, is straightforward and fast, making it ideal for quick turnarounds.

Maintenance Requirements

Both UV DTF and DTG printers require regular maintenance. UV DTF printers may need more frequent cleaning to avoid ink clogs, while DTG printers need consistent head cleaning and ink management.

Environmental Impact

UV DTF printers use UV-cured inks, which are generally less harmful to the environment than solvent-based inks. DTG printing uses water-based inks, which are eco-friendlier but require significant water use for pre-treatment and cleaning.

Choosing the Right Printer for Your Needs

Factors to Consider

When deciding between UV DTF and DTG, consider your specific needs: the type of materials you will print on, your budget, and the required print quality.

Application Scenarios

For businesses that need to print on a variety of material surfaces, UV DTF printers are the better choice. DTG printers are ideal for custom apparel printing businesses focused on cotton-based products.

Future Trends in Printing Technologies

Both UV DTF and DTG technologies are evolving. UV DTF printing is expanding its material range and efficiency, while DTG printing is improving its ink formulations and speed.

Both UV DTF and DTG printers have their unique advantages and are suited for different applications. Understanding your specific needs and the strengths of each technology will guide you to the right choice. Whether it’s the versatility of UV DTF or the ease of DTG, your decision should align with your business goals and printing requirements.