Do I Need a Special Printer for DTF Transfers?

While DTF printing is a relatively new technology in the digital marketing and custom apparel industry, it requires specific equipment to achieve high-quality results.Let’s delve into the details of what kind of printer you’ll need for DTF transfers.

Types of Printers for DTF

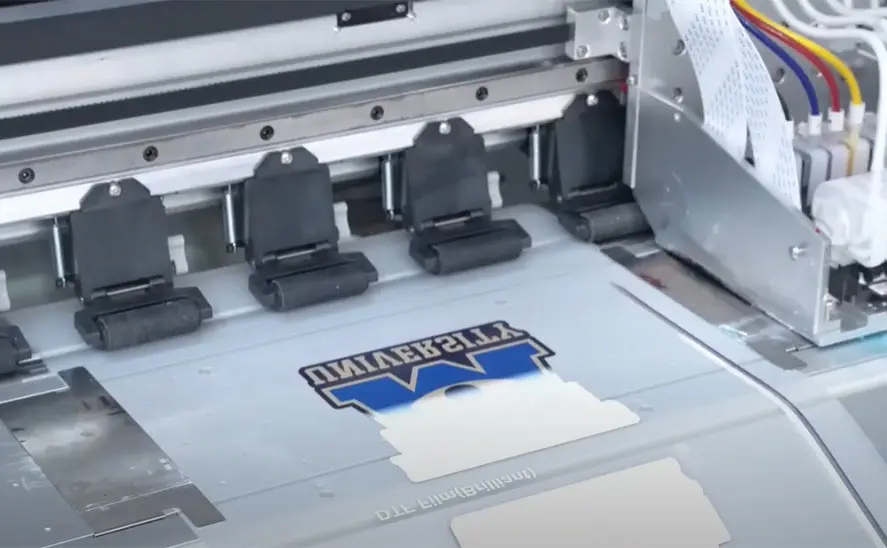

When it comes to DTF printing, the short answer is yes — you do need a special printer. DTF printers are typically modified inkjet printers that use special DTF inks and can print onto PET film. For DTF transfers, we recommend using a dedicated DTF printer or converting an existing inkjet printer. These printers are well-suited for DTF printing due to their excellent print quality and ease of adaptation.

What Makes a Printer Suitable for DTF?

Several factors determine whether a printer is suitable for DTF printing:

Ink Compatibility: DTF printing requires special textile inks that are thicker and more vibrant than standard inkjet inks. A standard printer must be able to handle these inks without clogging or damaging the printhead.

Printhead Technology: Printers with piezoelectric printheads are ideal for DTF. These printheads use a mechanical process to eject ink, making them more compatible with thicker DTF inks.

Film Printing Capability: A printer must be able to print on PET film, which is a different material than traditional paper. Some printers may require modifications to handle this type of substrate effectively.

printer for dtf

Modifying Printers for DTF Transfers

If you’re starting with a standard inkjet printer, modifications are essential to convert it for DTF use. Here are the key modifications required:

1. Installing DTF Ink

Regular inkjet printers use dye or pigment-based inks, which are not suitable for DTF printing. DTF printers use special inks formulated for heat transfers, including white ink for printing on dark fabrics. The white ink lays a base layer that allows the colors to pop on dark textiles.

2. White Ink Circulation System

One unique feature of DTF printers is the need for a white ink circulation system. White ink is denser than other colors, so it tends to settle and clog the printhead if not circulated regularly. Some DTF printers are equipped with a white ink circulation system, ensuring the ink stays in motion and prevents clogs.

3. Software Adjustments

Modifying a printer for DTF printing often involves software adjustments to control the print sequence. This ensures that the white ink is printed last, creating a base layer that enhances color vibrancy.

Why Specialized DTF Printers Are Better?

While it is possible to convert a regular inkjet printer for DTF printing, investing in a specialized DTF printer can offer several advantages:

1. Enhanced Print Quality

Specialized DTF printers are designed specifically for printing on film and transferring designs to fabric. As a result, they produce higher-quality prints with sharper details, smoother gradients, and better color accuracy compared to modified inkjet printers.

2. Improved Efficiency

DTF printers are optimized for speed and efficiency, making them ideal for businesses with high production needs. A specialized DTF printer can print more designs per hour, reducing downtime and increasing productivity.

3. Reduced Maintenance

Because they are purpose-built for DTF printing, specialized printers require less maintenance than modified inkjet printers. Features like automated white ink circulation systems and self-cleaning printheads help prevent clogs and ensure consistent print quality.

Printing DTF Transfers | DTF Printer

Advantages of DTF Printing

There are several reasons why DTF printing is becoming a popular choice for custom apparel businesses:

1. Versatility

DTF printing works on a wide variety of fabrics, including cotton, polyester, blends, and even leather. This flexibility makes it an ideal choice for printing on different garments and textiles.

2. Durability

DTF transfers are known for their durability. The designs are resistant to washing and stretching, ensuring that your custom garments maintain their vibrant appearance over time.

3. Vibrant Colors

One of the standout features of DTF printing is its ability to produce vibrant, eye-catching designs. The inks used in DTF printing are designed to deliver rich, saturated colors that pop on both light and dark fabrics.

4. No Need for Pre-Treatment

Unlike DTG (Direct-to-Garment) printing, DTF printing does not require pre-treating the fabric. This saves time and reduces the cost of materials, making DTF a more efficient option for high-volume printing.

dtf transfers

How to choose a printer for DTF transfers?

When selecting a printer for DTF transfers, look for the following key features:

Wide-format capabilities: Your printer should be able to handle A3 size or larger prints, allowing you to create a variety of transfer sizes for different marketing materials.

Ability to handle thicker films: DTF printing requires special transfer films, so your printer must be able to feed and print on these materials without jamming.

Precise droplet control: This feature ensures that your prints have fine details and smooth color gradients, which is crucial for high-quality marketing materials.

Compatibility with DTF inks: Your printer must be able to use specialized DTF inks, which are formulated to adhere to the film and transfer effectively to various fabrics.

It’s important to note that while you can convert some existing inkjet printers for DTF use, it’s often more reliable to invest in a dedicated DTF printer. These purpose-built machines are designed to handle the specific requirements of DTF printing, ensuring consistent results and reducing the likelihood of technical issues.

In summary, while you can modify a standard inkjet printer for DTF printing, investing in a specialized DTF printer is highly recommended. Specialized printers offer superior print quality, improved efficiency, and reduced maintenance, making them a better long-term investment for businesses looking to produce high-quality custom garments. Whether you are just starting or expanding your custom apparel business, the right equipment will play a crucial role in the success of your DTF printing endeavors.