Crafters’ Guide: Sublimation Beer Mug Printing Tips

Sublimation printing has become increasingly popular among crafters for its ability to create vibrant and long-lasting designs on various surfaces. One area where sublimation printing has found great success is on beer mugs. In this guide, we will explore the art of sublimation beer mug printing and provide you with expert tips to ensure your creations are flawless every time.

Understanding Sublimation Beer Mug Printing

Sublimation printing involves transferring dye onto a substrate using heat and pressure. The process starts by printing the design onto a special sublimation paper using sublimation ink. The paper is then placed onto the beer mug, and both are subjected to high heat and pressure in a heat press machine. The heat and pressure cause the ink to vaporize and penetrate the surface of the mug, creating a permanent and vibrant design.

Importance of Sublimation Printing on Beer Mugs

The popularity of sublimation printing on beer mugs has surged in recent years, thanks to its unique ability to combine personalization with functionality.

Personalization and Customization

Crafters can unleash their creativity by personalizing beer mugs with intricate designs, ensuring each piece is one-of-a-kind.

Durability and Long-lasting Prints

Sublimation prints on beer mugs boast exceptional durability, making them suitable for everyday use without fear of fading or peeling.

Tips for Sublimation Beer Mug Printing

If you want to achieve professional printing results, please pay attention to the following tips during the sublimation process:

1. Choose the Right Mug

When selecting a beer mug for sublimation printing, it’s important to choose one with a coating specifically designed for sublimation. These mugs have a polymer coating that allows the ink to bond properly with the surface, resulting in a high-quality print. Avoid using regular ceramic or glass mugs, as they won’t yield the same level of clarity and durability.

2. Prepare the Mug Surface

Before printing, make sure to clean the mug thoroughly to remove any dust, oils, or fingerprints. Use isopropyl alcohol and a lint-free cloth to wipe down the surface. This step ensures proper ink adhesion and prevents any unwanted imperfections in the final print.

3. Use High-Quality Sublimation Ink and Paper

Investing in high-quality sublimation ink and paper is crucial for achieving vibrant and long-lasting prints. Subpar ink or paper can result in dull colors or fading over time. Look for reputable brands that are known for their color accuracy and durability.

4. Ensure Proper Heat and Pressure

Proper temperature and pressure are critical for a successful sublimation print. Follow the guidelines provided by your ink and mug manufacturer for the recommended heat and pressure settings. It’s important to note that different mugs may require slight adjustments in temperature and pressure, so always test a small batch before proceeding with a larger order.

5. Pay Attention to Design Placement

When printing on beer mugs, consider the handle and lip of the mug. Ensure that your design is appropriately placed, taking into account the handle’s position and any gaps or curves on the mug’s surface. This attention to detail will result in a more professional and visually appealing finished product.

6. Use Heat-Resistant Tape

To prevent the sublimation paper from shifting during the heat press process, use heat-resistant tape to secure it in place. This will ensure that your design stays aligned and doesn’t blur or distort during printing.

7. Time and Pressure Management

Pay close attention to the recommended time and pressure settings for your chosen mug and equipment. Timing is crucial, as under- or over-pressing can affect the quality of the print. Use a timer to ensure accurate timing, and adjust the pressure as needed to achieve even and consistent results.

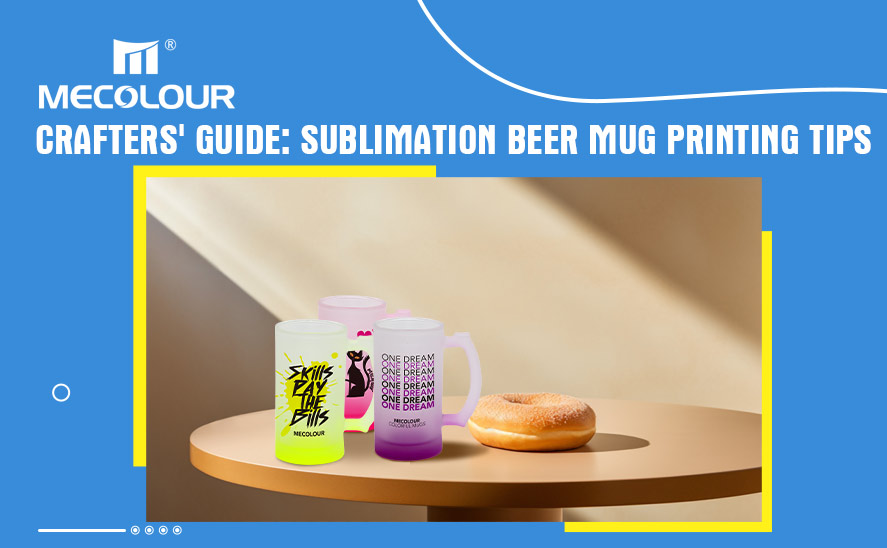

Mecolour Sublimation Gradient Color Frosted Glass Mug

8. Post-Printing Care

After printing, allow the mug to cool completely before handling or packaging. This ensures that the ink has fully cured and maximizes the durability of the print. Avoid using abrasive materials or harsh chemicals when cleaning the mug, as this can damage the design. Instead, opt for gentle hand washing with mild soap and warm water.

Sublimation beer mug printing opens up a world of creative possibilities for crafters. By following these expert tips, you can ensure that your sublimation prints on beer mugs are flawless every time. If you still have questions about the sublimation printing process of beer mugs, please feel free to follow our youtube video or contact us anytime!

Related:

2024 Cheers: Custom Beer Mugs for Every Event

Sublimation Ceramic vs. Glass Mugs: How to choose?

FAQs

Yes, as long as the mug has a smooth, polymer-coated surface suitable for sublimation.

Wear protective gear, such as heat-resistant gloves and safety glasses, to prevent burns.

Handwashing is recommended to preserve the longevity of the prints.

Mecolour is your reputable supplier and specialized craft manufacturer offer high-quality sublimation ink and mugs.