Coated mugs and uncoated mugs are two different types of mugs that differ in material and use. Let’s learn some ways to achieve personalized printing on coated or uncoated mugs.

What are coated mugs and uncoated mugs?

A coated mug is a mug that has a special layer applied on its surface. This coating is typically made of polymer or ceramic material, providing protection and decorative effects. Coated mugs are known for their smooth, durable, and corrosion-resistant properties, making them easy to clean and more long-lasting. The coating can also offer additional insulation, keeping hot drinks hot and cold drinks cold for longer periods.

On the other hand, an uncoated mug refers to a mug that does not have any special coating applied to its surface. These mugs are typically made of materials such as glass, ceramic, or stainless steel. Without a coating, uncoated mugs may be more susceptible to wear and corrosion. However, uncoated mugs often have a natural texture and appearance, making them suitable for specific purposes such as wine tasting or providing a unique coffee experience.

When choosing between coated and uncoated mugs, factors such as personal preference, intended use, and budget can be considered. Coated mugs offer better durability and insulation, making them suitable for everyday use and commercial purposes. Uncoated mugs, on the other hand, focus more on the natural texture and appearance of the material, appealing to consumers who value the beauty of simplicity.

What are the printing methods for coated mugs?

There are several printing methods for coated mugs, each with its own advantages and techniques. Here are some common printing methods used for coated mugs:

UVDTF Printing (UV Digital Transfer Film Printing)

UVDTF printing is a popular method for printing on coated mugs. It involves using UV-curable inks and a transfer film to transfer the design onto the cup’s surface. The film is placed on the cup, and UV light is used to cure the ink, resulting in a vibrant and durable print.

If you are interested in knowing the detailed transfer method, please watch this video.

Screen Printing

Screen printing is a traditional and widely used method for printing on coated mugs. It involves creating a stencil (screen) with the desired design and using it to transfer ink onto the cup’s surface. Screen printing allows for precise and high-quality prints, making it suitable for detailed and multicolor designs.

Sublimation Printing

Sublimation printing involves printing the design onto a special transfer paper using sublimation inks. The paper is then placed on the coated cup, and heat is applied, causing the ink to transfer onto the cup’s surface. This method produces vibrant and long-lasting prints.

How to print tumblers with 30oz portable mug press machine?

Pad Printing

Pad printing is a versatile printing method suitable for irregular or curved surfaces like coated mugs. It uses a silicone pad to transfer ink from an engraved plate onto the cup. Pad printing offers excellent detail and color reproduction.

Digital Printing

Digital printing allows for direct printing of designs onto coated mugs using specialized printers. This method is ideal for short runs or personalized prints as it offers quick setup and high-quality results.

Each of these printing methods has its own set of requirements, advantages, and limitations. The choice of method often depends on factors such as the desired print quality, complexity of the design, quantity of cups to be printed, and budget constraints.

What are the printing methods for mugs without coating?

Here are some common printing methods used for mugs without coating:

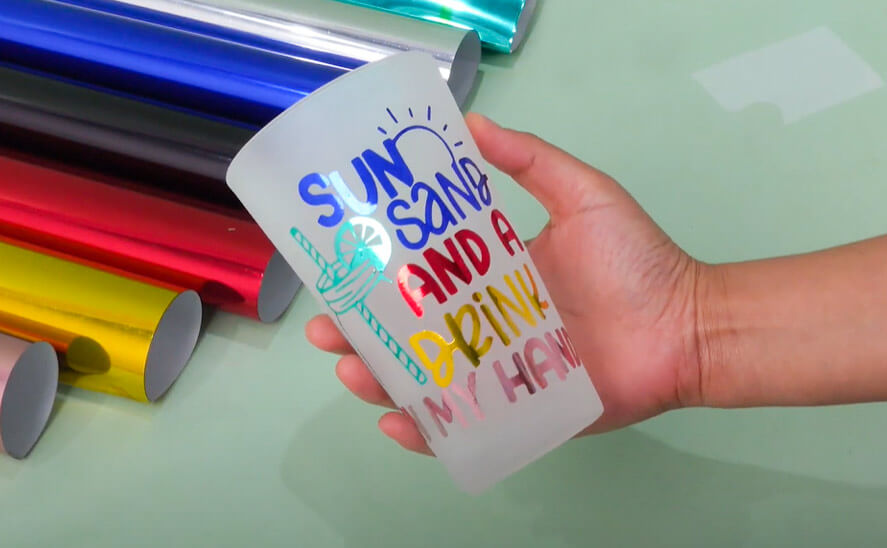

Vinyl Decals

Vinyl decals are adhesive stickers that can be applied to non-coated cups. The design is printed onto vinyl material, and the decal is then cut into the desired shape and applied to the cup’s surface. Vinyl decals offer flexibility in terms of design and can be easily customized. It should be noted that the sticker should be selected suitable for the surface material of the cup, and ensure that the sticker is water-resistant and wear-resistant.

Permanent Adhesive Vinyl

Permanent adhesive vinyl personalized mugs are a durable and personalized option that allows for a personalized transfer of your mug’s graphics using vinyl. Permanent adhesive vinyl is a durable and long-lasting material that will remain on the cup surface for a long time without fading or wear. This method is suitable for small batch customization or DIY projects.

If you are interested in the details of this transfer method, please follow the video.

Water Transfer Printing

Water transfer printing is a printing method that prints patterns on a water film and then transfers the water film to the surface of the cup. Complex patterns and gradient effects can be achieved this way. Water transfer printing can create unique visual effects on cups, but compared to other printing methods, it may require more professional equipment and technology.

If you are interested in the details of water transfer on mugs, please follow the video.

Engraving Method

In addition to printing, uncoated mugs can also be engraved to achieve exquisite designs. Engraving involves using a laser or engraver tool to carve a pattern into the surface of the mug. Engraving uses a chemical reaction to etch patterns out of the metal-coated mug. These methods are suitable for creating permanent patterns and personalized coated mugs.

Engraving metal-coated mug

It’s important to note that each printing method has its advantages and disadvantages. Consider factors such as budget, desired print quality, and durability when choosing the right method for your coated or non-coated mug. Additionally, working with a professional printing service that specializes in mug printing can help ensure the best results.

Whether you purchase coated or uncoated mugs, MECOLOUR can provide you with a quality product. We have a variety of mug types to suit a variety of printing methods and techniques, ensuring you get a satisfactory result.

Please feel free to contact us and we will be happy to assist you and answer any questions you may have.

Related:

How to make sublimation coating for mugs?

Types of Coated mugs and Printing Methods