Mastering Manual Tumbler Press Techniques

The tumbler press machine is a versatile tool used in the process of sublimating designs onto various cylindrical objects, such as tumblers and mugs. This article will provide a comprehensive guide on mastering the techniques of using a manual tumbler press machine, including how to use it, the materials and substrates involved, the target niche market, and tips for achieving optimal results.

What is a Tumbler Press Machine?

A tumbler press machine is a heat press device specifically designed for sublimating designs onto tumblers. It consists of multiple stations, an auto-release design, interchangeable heaters, pressure adjustment, and temperature and time settings. These features allow for precise control over the sublimation process, ensuring high-quality and long-lasting results.

How to Use a Tumbler Press?

Using a tumbler press involves a step-by-step process. First, prepare the tumbler by cleaning it thoroughly and ensuring that the surface is free of any dust or contaminants. Next, print the desired design onto sublimation paper using sublimation ink. Place the printed design around the tumbler, making sure it is properly aligned. Secure the paper in place using heat-resistant tape. Then, preheat the tumbler press to the recommended temperature and adjust the pressure accordingly. Place the tumbler inside the press, ensuring that the design is facing the heater. Close the press and set the desired time. Once the time is up, open the press, remove the tumbler, and peel off the sublimation paper. Finally, allow the tumbler to cool down before handling it.

how to use tumbler press

Materials and Substrates for Tumbler Press

The materials and substrates used in tumbler pressing include sublimation paper, sublimation ink, and various types of sublimation drinkware blanks made of materials such as stainless steel, aluminum, glass and ceramic. It is important to choose high-quality sublimation paper and ink to ensure vibrant and durable designs. Additionally, selecting tumblers with a smooth and coated surface will result in better adhesion of the sublimation ink.

Materials and Substrates for Tumbler Press

Target Niche Market for Tumbler Pressing

The target niche market for tumbler pressing is vast, as personalized and customized tumblers have become increasingly popular. Tumblers offer a practical and stylish way for individuals to showcase their personal preferences, hobbies, or branding. This niche market includes individuals, businesses, sports teams, event organizers, and gift shops, among others. Tumbler pressing allows them to create unique and eye-catching designs that cater to their specific needs and preferences.

What Does a Tumbler Press Do?

A tumbler press machine serves several purposes in the sublimation process. It provides the necessary heat and pressure to transfer sublimation ink from the printed sublimation paper onto the tumbler’s surface. The heat activates the ink, turning it into a gas that permeates the coating on the tumbler, resulting in a permanent and vibrant design. The pressure ensures proper contact between the sublimation paper and the tumbler, facilitating the ink transfer process.

Tumbler Press Techniques for Optimal Results

To achieve the best outcomes when using a tumbler press, consider the following techniques:

A. Multiple Stations

A tumbler press with multiple stations allows for efficient production by providing space for multiple tumblers to be pressed simultaneously. This is particularly beneficial for businesses with high-volume orders or for individuals looking to streamline their production process.

Multiple Stations

B. Auto-release Design

An auto-release design feature allows for quick and easy removal of the tumbler after the pressing process is complete. This minimizes the risk of accidental burns and increases overall productivity.

C. Interchangeable Heaters

Tumbler presses with interchangeable heaters offer versatility by accommodating different sizes and shapes of tumblers. This allows for greater flexibility in the types of designs and substrates that can be used.

D. Pressure Adjustment

The ability to adjust the pressure ensures that the sublimation ink is properly transferred onto the tumbler’s surface. It is important to find the right balance of pressure to achieve a vivid and long-lasting design.

E. Temperature & Time Settings

Correct temperature and time settings are crucial for successful sublimation. Follow the manufacturer’s recommendations for the specific type of sublimation paper, ink, and tumbler being used. Proper temperature and time settings ensure that the ink fully sublimates and adheres to the tumbler’s surface.

Sublimating a Tumbler with a Tumbler Press Machine

To sublimate a tumbler using a tumbler press machine, you will need essential items such as sublimation paper, sublimation ink, heat-resistant tape, and a heat-resistant glove. Additionally, referring to a step-by-step guide video can be helpful in understanding the entire process. Here is a general overview of the sublimation process:

A. Essential Items for Beginning Tumbler Sublimation:

Sublimation paper

Sublimation ink

Heat-resistant tape

Heat-resistant glove

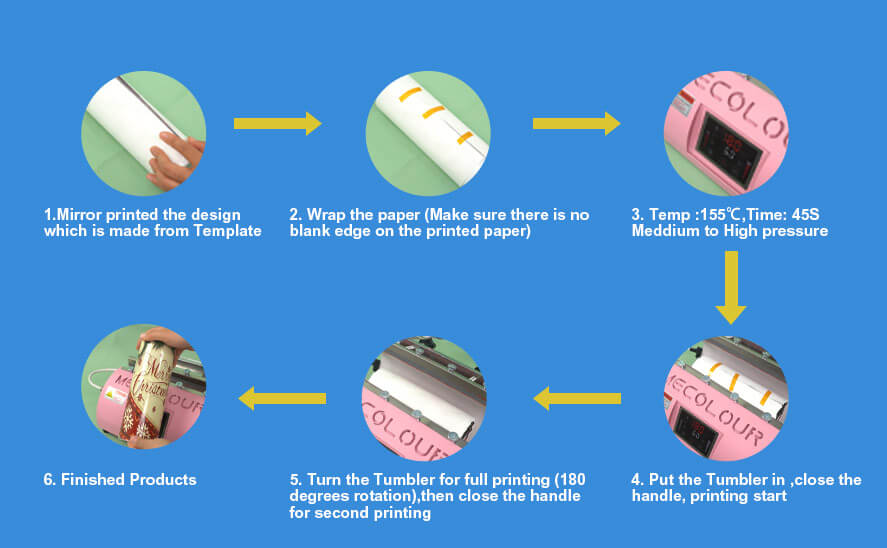

B. Tumbler Sublimation Step-by-Step Guide Video:

Prepare the tumbler by cleaning it thoroughly.

Print the desired design onto sublimation paper using sublimation ink.

Wrap the printed design around the tumbler and secure it with heat-resistant tape.

Preheat the tumbler press to the recommended temperature.

Adjust the pressure according to the manufacturer’s guidelines.

Place the tumbler inside the press, ensuring that the design is facing the heater.

Close the press and set the desired time.

Once the time is up, open the press, remove the tumbler, and peel off the sublimation paper.

Allow the tumbler to cool down before handling it.

C. Pro Tips to Enhance Tumbler Press Outcomes:

Use high-quality sublimation paper and ink for vibrant and durable designs.

Choose tumblers with a smooth and coated surface for better ink adhesion.

Ensure proper alignment and secure the sublimation paper tightly around the tumbler.

Follow the recommended temperature and time settings for the specific materials used.

Experiment with different pressure levels to find the optimal setting for desired results.

How to use tumbler heat press machine for 20oz Straight Sublimation Skinny Tumblers?

Tumbler Press Settings: Temperature, Time, and Pressure

The specific tumbler press settings depend on various factors, including the type of sublimation paper, ink, and tumbler being used. It is essential to follow the manufacturer’s recommendations for the best results, because temperatures and times vary from manufacturers and products. Generally, the temperature for sublimation ranges from 350 to 400 degrees Fahrenheit, with a pressing time of around 45 to 90 seconds. The pressure should be adjusted to ensure proper contact between the sublimation paper and the tumbler.

Best Tumbler Heat Press Machine

Choosing the best tumbler heat press machine depends on individual needs and preferences. Some of the popular options in the market include brands like Mecolour that offer machines in various sizes and features to customers across the globe. When selecting a tumbler press machine, consider factors such as build quality, durability, heat distribution, ease of use, and customer reviews. It is also important to ensure that the machine is compatible with the size and type of tumblers you intend to use.