Frosted glass beer mugs are a popular choice for personalized drinkware, and sublimation printing offers an excellent way to create stunning designs on these mugs. Sublimation allows for vibrant and durable prints that will withstand regular use and washing. In this blog post, we will guide you through the process of sublimating frosted glass beer mugs using a mug press.

What You’ll Need in sublimation printing

Before you get started, make sure you have the following items:

Frosted glass beer mugs: Ensure they are clean and free from any dust or dirt.

Sublimation paper: Special paper that allows the ink to transfer onto the mug’s surface.

Sublimation ink: High-quality ink specifically designed for sublimation printing.

Heat-resistant tape: To secure the sublimation paper onto the mug.

Heat-resistant gloves: To protect your hands during the sublimation process.

Mug press: A heat press machine designed for sublimating mugs.

Heat-resistant pad or silicone wrap: To protect the mug press and ensure even heat distribution.

Step-by-Step Guide

Now, let’s dive into the step-by-step process of sublimating frosted glass beer mugs with a mug press:

Step 1: Design and Print

Start by creating your desired design using graphic design software or a sublimation-specific design tool.

Mirror your design horizontally before printing it onto sublimation paper.

Load the sublimation paper into your printer and ensure the design is printed onto the correct side of the paper.

Step 2: Preparing the Mug

Clean the frosted glass beer mug thoroughly with mild detergent and warm water. Make sure to remove any dust, fingerprints, or grease.

Dry the mug completely with a lint-free cloth to ensure proper adhesion of the design.

Wrap the sublimation paper around the mug, positioning the design in the desired location.

Secure the sublimation paper with heat-resistant tape, ensuring it is tightly wrapped around the mug.

Step 3: Mug Press Setup

Preheat your mug press to the recommended temperature for sublimating frosted glass. Refer to the manufacturer’s guidelines for the specific temperature.

Place a heat-resistant pad or silicone wrap inside the mug press to provide even heat distribution and protect the press from any residual ink or adhesive.

Step 4: Sublimation Process

Put on heat-resistant gloves to protect your hands during the sublimation process.

Carefully place the wrapped frosted glass beer mug into the mug press, ensuring it is centered and aligned correctly.

Close the mug press and apply firm pressure. Set the timer according to the sublimation paper and ink manufacturer’s recommendations.

Once the timer goes off, open the mug press and carefully remove the mug using heat-resistant gloves. Be cautious as the mug will be hot.

Place the hot mug on a heat-resistant surface and allow it to cool down completely. This will ensure the design sets properly.

Step 5: Finishing Touches

Once the mug has cooled down, remove the sublimation paper and tape. Peel them off gently to avoid damaging the design.

Inspect the mug for any imperfections or areas that may require touch-ups. If needed, you can use sublimation markers or heat-resistant paint to fix minor issues.

Clean the mug again to remove any residual ink or adhesive. Use mild detergent and warm water, and avoid using abrasive materials that may scratch the mug’s surface.

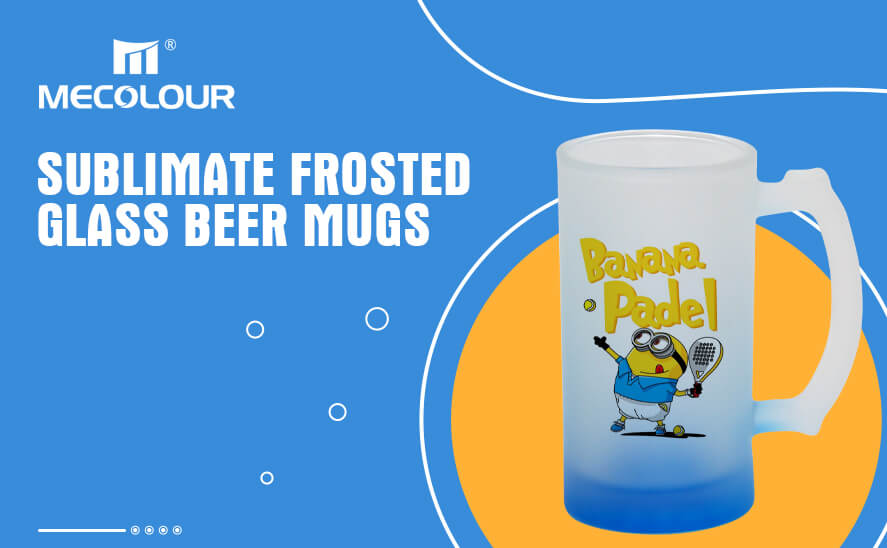

Mecolour Sublimation Customized Gradient Color Frosted Glass Mug

Congratulations! You have successfully sublimated your frosted glass beer mug using a mug press. Admire your personalized design and enjoy your unique drinkware.

Tips for Best Results

Here are some additional tips to ensure the best results when sublimating frosted glass beer mugs:

Use high-quality sublimation paper and ink for vibrant and long-lasting designs.

Follow the recommended time, temperature, and pressure settings provided by the sublimation paper and ink manufacturer.

Experiment with different design placements and orientations to find the most visually appealing option for your mug.

Avoid excessive handling of the mug during and after the sublimation process to prevent smudging or damage to the design.

Always refer to the specific guidelines and recommendations provided by the mug press manufacturer for optimal sublimation results.

With the sublimation process mastered, you can now create personalized frosted glass beer mugs for yourself, loved ones, or even as unique gifts. Enjoy the process of designing and sublimating your own customized drinkware!

7 Gradient colors for your choice

If you’re in search of high-quality sublimation blanks for your printing business, look no further than Mecolour. As a leading supplier of sublimation mugs, we offer a wide range of products to meet the diverse needs of our global customers. With our commitment to excellence and dedication to customer satisfaction, Mecolour is the trusted choice for sublimation enthusiasts and professionals alike.