Can you use a mug press for a tumbler? Regarding this question, first of all, we need to know what the shape of your so-called tumbler is, and secondly, what is the material of your tumbler, whether there is a sublimation coating, and what kind of transfer effect you want to achieve. Before you sublimate a mug, you must be clear that is your design is monochrome or multi-color, whether there is gradient color? Then you can know what kind of mug press machine and printing method is the most suitable for you.

What I just said above can be simply divided into three printing methods:

1.Dye-sublimation transfer printing

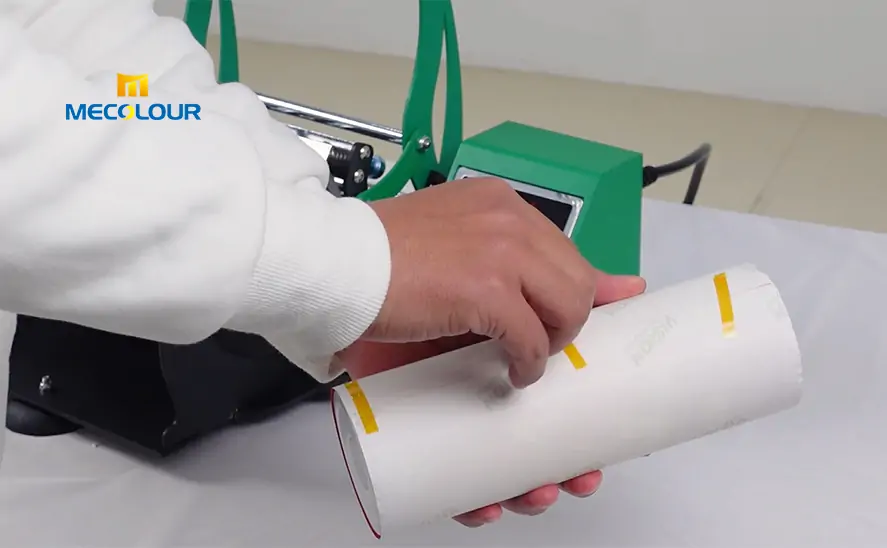

This is the most used printing method in our industry. It usually requires the use of mug press machines or ovens, sublimation paper, and tumbler with sublimation coating. The material is usually stainless steel tumblers. Then look at the shape of the cup. If it is a straight cup, then you must choose a suitable cup heat press machine according to the size of the cup. Generally speaking, 20 OZ tumbler heat press and 30 OZ mug press machines are used most. If the shape is special, such as a little curvature, Or simply conical, then you need to match the conical baking coaster, or use heat shrinkable film with the oven to achieve the transfer. The advantage of using this method of transfer is that there are various colors, and basically you don’t have to worry about it will fade, and the success rate is relatively high, as long as you try a few times, you can basically master the method.

2. Screen printing

This kind of printing method has no major requirements for the tumbler material, and does not require a special coating for the cup, but the printing machine itself is relatively expensive, and a machine can usually only print one color , usually you need to match a screen printing template and ink. You can find a local carpenter or professional to make the screen printing template. The ink matching is proportional. This also requires many attempts. The biggest advantage of this printing method is that it is convenient to print and high in efficiency, but it has limitations. Usually, it can only be monochrome. If it is registered, the alignment requirements are relatively high, and it needs professional debugging before it can actually be put into production.

3. Uncoated printing

This kind of cup does not need sublimation coating, the machine used is basically only a 360°C heat press machine and a laser printer (hp, fuji or OKI), the cup There is no requirement for the material. The paper is special. It needs to be matched with a laser-printed uncoated paper. We sell this, and the investment is relatively small, but the transfer effect that can be achieved is not very high. Photos It is definitely not good for high-level. Generally, we recommend using it for logo printing, and it is not recommended to print full-size, and there is a possibility of failure.

4. Laser engraving

The last one is laser engraving. This is a new machine that we plan to launch recently. The effect achieved is basically gray or black, but the pattern must be fine, but it will definitely be difficult for novices.

Mecolour is a top China sublimation blanks factory specializing in the production of all kinds of sublimation blanks consumables. So now you know what kind of printing mug press can do, if you want to know more, you can visit our MECOLOUR website, or send me an email to [email protected], I will do more answers for you.