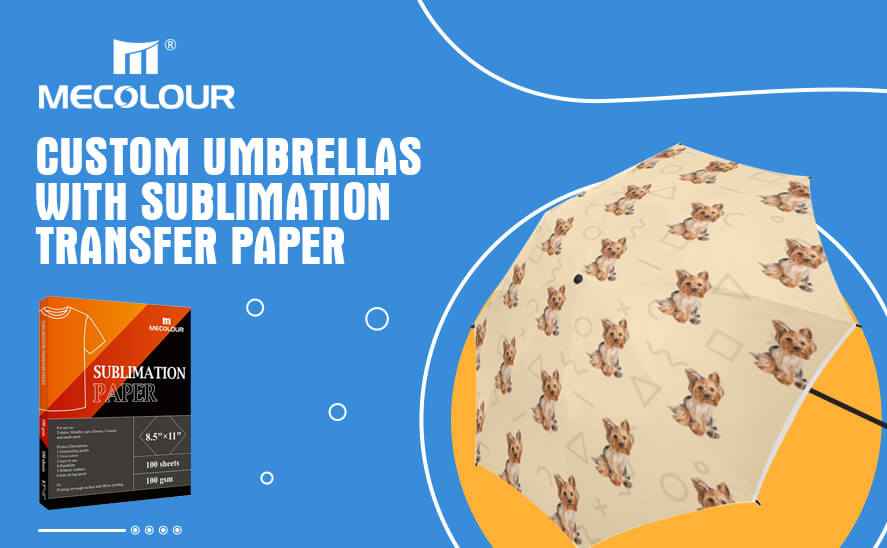

Custom umbrellas are a popular promotional item for businesses, events, and organizations. They offer a practical and functional way to showcase branding and messaging while providing protection from the elements. One popular method for creating custom designs on umbrellas is by using sublimation transfer paper. In this article, we will explore the process of creating custom umbrellas with sublimation transfer paper, the advantages of this technique, and some tips for achieving high-quality results.

Sublimation Transfer Paper for Custom Umbrellas

Understanding Sublimation Transfer Paper

Sublimation transfer paper is a specialized type of paper that is used in the sublimation printing process. Sublimation printing involves transferring dye onto a substrate, such as fabric or coated materials, using heat and pressure. The sublimation transfer paper acts as a carrier for the dye, allowing it to be transferred onto the umbrella fabric during the heat press process.

Advantages of Sublimation Transfer Paper for Custom Umbrellas

Vibrant and Long-lasting Prints: Sublimation transfer paper produces vibrant and high-resolution prints that are durable and long-lasting. The dye is infused into the fabric, resulting in a design that won’t fade, crack, or peel over time.

Full-color Printing: Sublimation transfer paper allows for full-color printing, making it ideal for complex and detailed designs. It can reproduce gradients, photographs, and intricate patterns with precision.

Seamless Printing: With sublimation transfer paper, the design can be printed edge-to-edge on the umbrella fabric, creating a seamless and professional look.

Breathable and Washable: Sublimation prints are breathable and do not affect the functionality of the umbrella. The prints are also washable, ensuring that the custom design stays intact even after regular use.

To create custom umbrellas using sublimation transfer paper, you will need the following:

Sublimation printer: You will require a printer that is compatible with sublimation inks. These printers use special inks that can turn into a gas when exposed to heat and bond with the polyester fibers of the umbrella fabric.

Sublimation inks: Sublimation inks are formulated to work with sublimation transfer paper and are available in various colors. These inks are converted into a gas during the heat transfer process, allowing them to penetrate the fabric fibers and create vibrant and durable prints.

Sublimation transfer paper: Sublimation transfer paper has a special coating that helps the inks transfer onto the fabric. The design is printed onto the transfer paper using a sublimation printer, and then the paper is placed onto the umbrella fabric for the heat transfer process.

Process of Creating Custom Umbrellas with Sublimation Transfer Paper

Step 1: Designing the Artwork

The first step in creating custom umbrellas with sublimation transfer paper is to design the artwork. Using graphic design software, such as Adobe Photoshop or Illustrator, you can create a design that suits the branding or messaging requirements. It’s important to consider the size and dimensions of the umbrella when creating the design.

Step 2: Printing the Design on Sublimation Transfer Paper

Once the artwork is finalized, it needs to be printed onto the sublimation transfer paper. It’s crucial to use a sublimation printer and sublimation inks for this step. The design should be printed in mirror image to ensure that it transfers correctly onto the umbrella fabric.

Step 3: Preparing the Umbrella Fabric

Before transferring the design, it’s important to prepare the umbrella fabric. Ensure that the fabric is clean and free from any dust or debris. You may also need to pre-press the fabric to remove any moisture or wrinkles.

Step 4: Heat Pressing the Design onto the Umbrella

Using a heat press machine, the sublimation transfer paper with the printed design is placed onto the umbrella fabric. The heat press machine applies heat and pressure, causing the sublimation ink to convert into a gas and penetrate the fabric fibers. This process permanently embeds the design into the fabric.

Step 5: Finishing and Quality Control

After heat pressing, the umbrella needs to cool down before the transfer paper can be removed. Once cooled, the transfer paper is peeled off, revealing the vibrant and custom design on the umbrella fabric. It’s essential to inspect the print for any defects or imperfections before considering the customization process complete.

How to personalize sublimation umbrella? If you want to learn more videos,please follow our youtube.

Tips for Achieving High-Quality Results

To ensure high-quality results when creating custom umbrellas with sublimation transfer paper, consider the following tips:

Use High-Quality Sublimation Transfer Paper: Invest in good quality sublimation transfer paper that is specifically designed for fabric printing. This will ensure better color accuracy, durability, and overall print quality.

Choose the Right Umbrella Fabric: Not all umbrella fabrics are suitable for sublimation printing. Opt for fabrics that are polyester-based or have a high polyester content, as polyester fibers can effectively absorb and retain the sublimation ink.

Calibrate Your Heat Press Machine: Proper calibration of the heat press machine is crucial for achieving consistent and accurate results. Follow the heat press manufacturer’s instructions for temperature, pressure, and time settings to ensure optimal transfer of the design onto the umbrella fabric.

Conduct Test Prints: Before printing on the actual umbrellas, it’s advisable to conduct test prints on sample fabrics. This will help you fine-tune the printing settings and ensure that the colors and design are coming out as desired.

Handle with Care: Once the custom umbrellas are printed, it’s important to handle them with care to preserve the design. Avoid excessive rubbing, scratching, or folding that could damage or distort the print.

It’s important to note that the success of sublimation printing on umbrellas depends on the composition of the umbrella fabric. Umbrellas made of 100% polyester or polyester-blend fabrics usually yield the best results as the sublimation inks can bond effectively with the synthetic fibers.

If you’re new to sublimation printing or want high-quality results, it’s advisable to seek the assistance of a professional printing service that specializes in sublimation printing on umbrellas. They will have the expertise and equipment to ensure accurate printing and vibrant, long-lasting designs.